IAC - Plumbing the inlet?

Posted: Sat Oct 31, 2009 4:03 am

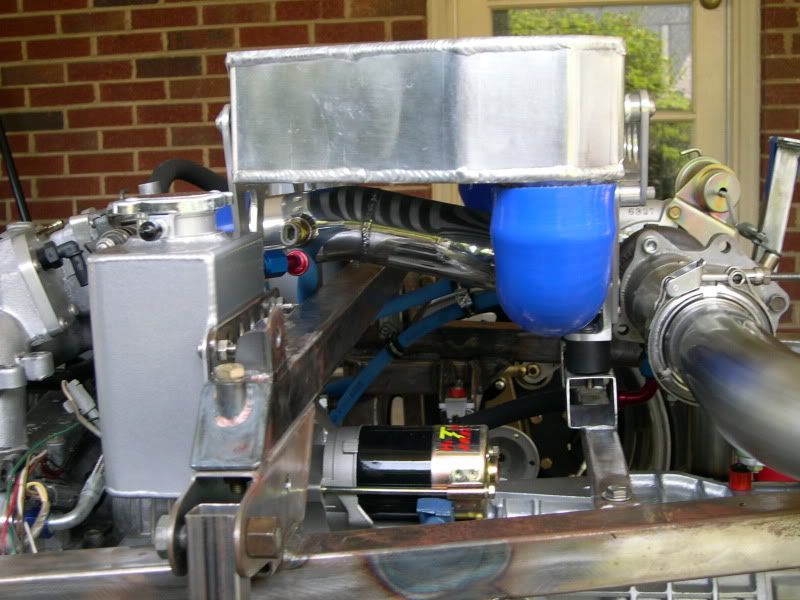

I have the remote mount DIYAutoTune IAC housing and Jeep valve. Intending to run this on a turbocharged Subaru engine.

I wanted to do away with the bulky OEM IAC valve both for aesthetic reasons and to simplify the installation for Megasquirt control. While deciding where to plumb the air inlet for the valve it occurred to me this could be a problem.

My original plan was to plumb it to the air intake tube, between air filter and turbo. Location is good, already filtered air - seemed like a good plan. As I though through the dynamics during operation though, maybe not such a good idea - if the valve has any leakage you have a perpetual manifold leak, bleeding off boost pressure? Anytime the valve is open (during warm-up) at least a large part of any boost created would be bled off. Any (even slight) leakage when the valve is closed - the perpetual leak situation.

OK, so what if we plumb it downstream of the turbo, between turbo and throttle body. In that situation you wouldn't encounter the perpetual leak since both sides of the valve would be under pressure. This sounds better - except in any situation when the valve is open, and you build boost, you've essentially created another throttle valve and could wind up with a run-away boost condition? Seems like a loose-loose situation!

What say the experts?

Jeff

I wanted to do away with the bulky OEM IAC valve both for aesthetic reasons and to simplify the installation for Megasquirt control. While deciding where to plumb the air inlet for the valve it occurred to me this could be a problem.

My original plan was to plumb it to the air intake tube, between air filter and turbo. Location is good, already filtered air - seemed like a good plan. As I though through the dynamics during operation though, maybe not such a good idea - if the valve has any leakage you have a perpetual manifold leak, bleeding off boost pressure? Anytime the valve is open (during warm-up) at least a large part of any boost created would be bled off. Any (even slight) leakage when the valve is closed - the perpetual leak situation.

OK, so what if we plumb it downstream of the turbo, between turbo and throttle body. In that situation you wouldn't encounter the perpetual leak since both sides of the valve would be under pressure. This sounds better - except in any situation when the valve is open, and you build boost, you've essentially created another throttle valve and could wind up with a run-away boost condition? Seems like a loose-loose situation!

What say the experts?

Jeff