If anyone can help, please reply. Im looking for input from those who have done it, and documented their process by photo. So PLEASE post pictures of wiring up your harness, where sensors go, everything. I'd then like to try and make this a "HOT-TO" for here, and club-4ag, or any other sites where this is a common interest....

Please do not post links to msefi, megamanual, or other techno babble. The purpose of this topic is for someone who knows nothing about Megasquirt or whats needed, and how to install it sucessfully with no required speciality except for general soldering/splicing skills and a decent tool set. Please try to only cover the basics: Engine control, starting circuit, charging circuit. As nice as gauges, AC, PS, fan control, diagnosis connectors, stuff for emissions, etc... are nice... they are not required to get the car starting and driveable. If the OEM Toyota sensor does not work with MS, please refer to the GM sensor that needs to be adapted, and if possible always show accompanying pictures. Also if wiring something differs depending on what version MS you have please try and make it so that us dummies comprehend. Finally, if there are required capacitors or resistors, etc.. please try and make it as clear as possible what you are describing to do.

For the purpose of the easiest and most widely known sucess and compatibility, this will be regarding standard bank injection with stock high impedance injectors, and the use of the EDIS-4. (Please show pictures)

If you plan on explaining what to do on the stock distributor or high impedance injectors, (please be prepared to post accompanying pictures step, by step, and with a clear diagram or dont post at all.)

Lastly, THANK YOU SO MUCH IN ADVANCE.

Let's get started!

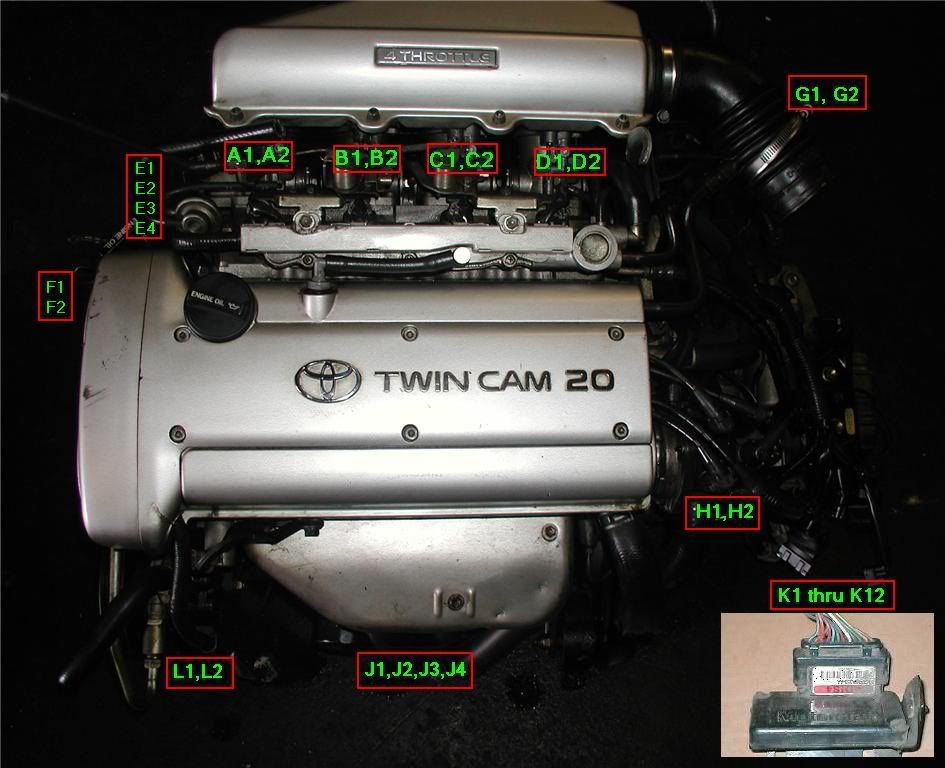

This is what Im working with:

I've labelled most of the basic sensors needed with its general location, etc, here is the key:

A1: Injector Power

A2: Injector Ground

B1: Injector Power

B2: Injector Ground

C1: Injector Power

C2: Injector Ground

D1: Injector Power

D2: Injector Ground

E1: Throttle Position Sensor - Pin 1

E2: Throttle Position Sensor - Pin 2

E3: Throttle Position Sensor - Pin 3

E4: Throttle Position Sensor - Pin 4

F1: VVTI - Pin 1

F2: VVTI - Pin 2

G1: Intake Air Temp Sensor - Pin 1

G2: Intake Air Temp Sensor - Pin 2

H1: Coolant Temp - Pin 1

H2: Coolant Temp - Pin 2

J1: O2 Sensor - Wire 1

J2: O2 Sensor - Wire 2

J3: O2 Sensor - Wire 3

J4: O2 Sensor - Wire 4

K1-K12: EDIS Pin 1-12

L1: VR Sensor 1

L2: VR Sensor 2

Below is the pinout for the MS harness from DIY Autotune:

Please help mix and match. I do know how to use a DVOM know exactly how electrical circuits work (atleast OEM ones), resistors, volts, ohms, amps, rosin core soldering, etc... But I'd like to have this so simple that even if I didn't know how those things worked or how to do those, I could still follow this page and figure out how to wire up the MS. Thanks.

Just some guesses on some connectors:

A1: Pin 32

A2: Pin 33

B1: Pin 34

B2: Pin 35

C1: Pin 32

C2: Pin 33

D1: Pin 34

D2: Pin 35

E1: ?

E2: ?

E3: ?

E4: ?

F1: ?

F2: ?

G1: Pin 20

G2: Pin 17, 18, or 19

H1: Pin 21

H2: Pin 17, 18, or 19

J1: O2 warming - 12v (switched)

J2: O2 warming - Grounded

J3: O2 signal positive: Pin 23

J4: O2 signal ground: Grounded

K1: Pin 24

K2: ?

K3: Pin 36

K4: ?

K5: L1

K6: L2

K7: ?

K8: ?

K9: ?

K10: ?

K11: ?

K12: ?

L1: K5

L2: K6

Is any of this even close to correct?[/img]