Does the GM stepper valve actually bottom out on the cone shaped bottom to the object it sits into?

Then at startup the motor will move to open (step=0), then immediately after go to whatever position is right based on the coolant temperature, say step = 50. This will all take place in about a second, probably before the engine ever fires. Then the motor will slowly move to the closed position as the coolant gets hot, which can be 110 if that is what is in your table of step vs. coolant temperature.

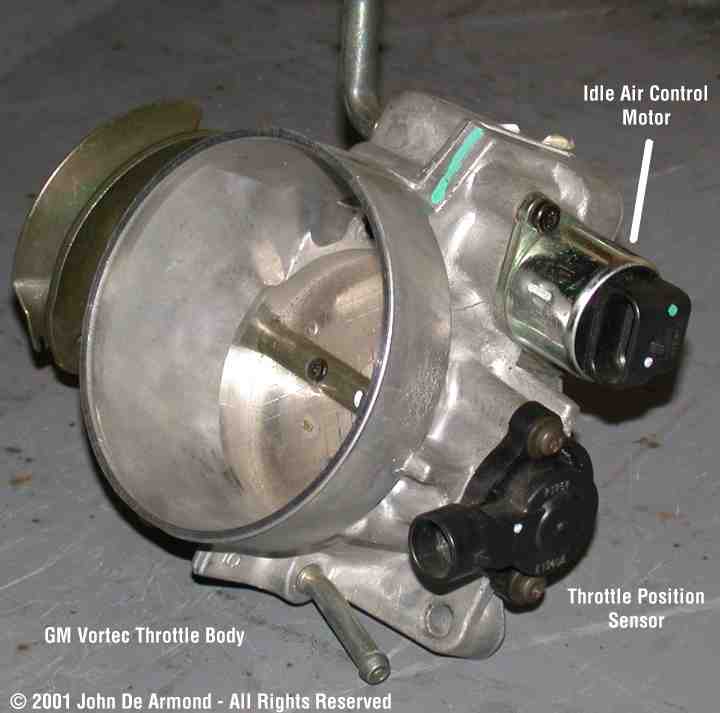

I am using a northstar TB which is similar to this one (from a vortec motor). The IAC is in the TB.panel wrote:Thanks guys! What I might do is make a fitting that one of these will fit into remotely. Then run some hose to the TB.

Any pics of what/where they are mounted on an OEM car?

I don't have any pics handy, but I found that mid-90s GM 2.8/3.1 had the IAC mounted in a removable body on the intake tract. Looks like it should be do-able for a remote mount if you fab up a block-off plate and some hosebarb fittings.panel wrote:Thanks guys! What I might do is make a fitting that one of these will fit into remotely. Then run some hose to the TB.

Any pics of what/where they are mounted on an OEM car?